Let us look at how to generate a command file for a simple Cantilevered beam analysis.

This beam is a RHS (Rectangular Hollow Section) with dimensions of 100 x 50 x 5 (Width x Height x Thickness)

It is fixed on one end and a load of 2000N is applied on the other end.

Fixed node is given a Node group name of “Fix” and the node on which Load is applied is given a Node group name of “Load” (how inventive)

The mesh is in MED format

So lets start generating command file for this analysis

Note: All screenshots are from a Windows 7 machine, using a different Operating system will not change the command file.

Step1:

Start Efficient (Click Here to see how to do that)

On the first tab, keep everything as default shown in screenshot below

Step2:

Click on Tab “Analysis Type” where we will select “Mechanical – Beam” in the left-top drop down box (highlighted yellow in screenshot below) and leave everything else as it is.

Step3:

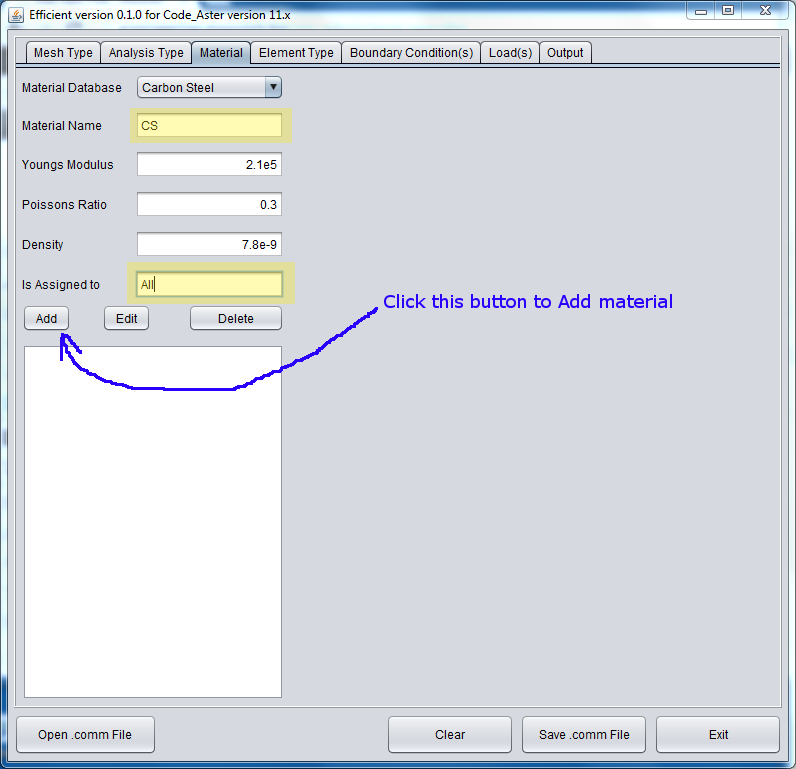

Click on Tab “Material” where we will add material to the analysis.

Enter “CS” for the Material Name

Keep default Youngs Modulus of 2.1e5 which is in MPa, Poisson’s Ratio of 0.3 and Density of 7.8e-9 (tonnes/mm^3)

Enter “All” for Is assigned to, to specify that entire Beam has this material.

Click on “Add” and the material will be added to the command file

Step4:

Click on Tab “Element Type” where we will add information about the beam element to the analysis.

Select “Beam” for Type of Element

Select “Rectangle” for Section Type

Enter “Guide” for Is assigned to, as this is the Name given to the Mesh Group for the Beam

Enter “5” for Thickness in Y (EY) (Y is the Width in local co-ordinate)

Leave blank for Thickness in Z (EZ) as the RHS has uniform thickness. (Z is the Height in local co-ordinate)

Enter “100” for Section Width (HY)

Enter “50” for Section Height (HZ)

Click on “Add” and the section property will be added to the command file

Step5:

Click on Tab “Boundary Condition(s)” where we will add information about the Fixed Boundary Condition to the analysis.

Select “D.O.F (DDL) on Node Group” for Type of Boundary Cond. as we are adding a boundary condition on Group of Node

Enter “Fixed” for Boundary Condition Name. This is required as this name will be used in the command file from now on. This can be the same as the Node Group name defined in the mesh, but it does not need to be the same. Make sure the length of the Boundary Condition Name is less than or equal to 8 (Limitation of Fortran).

Enter “Fix” for Is assigned to, which is the name of the Node Group name defined in the mesh. This has to be exactly the same name (case sensitive) as given in the mesh.

Enter “0” (Zero) for all DX, DY, DZ, DRX, DRY and DRZ as we want to make this node as an anchor. All 6 degrees of freedom needs to be defined here as Nodes on Beam have 6 degrees of freedom.

Click on “Add” and the boundary condition will be added to the command file.

Step6:

Click on Tab “Load(s)” where we will add information about the Loads to be applied to the analysis.

Enter “ForceZ” for Load Name, This is required as this name will be used in the command file from now on. This can be the same as the Node Group name defined in the mesh, but it does not need to be the same. Make sure the length of the Load Name is less than or equal to 8 (Limitation of Fortran).

Select “Force on Node” for Load Type as we will be applying a Force on a Node.

Enter “Load” for Is Assigned to, which is the name of the Node Group name defined in the mesh. This has to be exactly the same name (case sensitive) as given in the mesh.

Enter “2000” for FZ as we want to apply 2000N force in +Z direction.

Click on “Add” and the load will be added to the command file.

Step7:

Click on Tab “Output” where we will add information about the types of results that we want in the analysis.

Efficient is intelligent to know that the type of Analysis is “Beam” and so it showed only those output Options that are related to Beam analysis.

If you don’t ADD anything in this Tab, only Deflection will be saved in MED file

As we want all options that are available for this Analysis we will click “Add ALL”

Step8:

Now the only thing left is the Click “Save .comm File”, Efficient will ask for a location where you want to save this file, select a folder where you want the file to be saved and give it a name, Here I have given it a name “Beam.comm”. (Remember to add .comm at the end of the File name as by default this is not written by Efficient.

Click on “Save” and the file will be saved. Once Efficient has saved the file, it will show message as follows

Hurray, you have a working command file within few seconds.

Your comm file should look like below

############################### #File created by Efficient Software version 0.1.0 #Version of Code_Aster is 11.x #Author of Efficient is Dhramit Thakore #https://engineering.moonish.biz ###############################

#U4.11.01 #@Eff@#StartCont#DEBUT DEBUT();

#U4.21.01 #@Eff@#MeshType#MED mesh=LIRE_MAILLAGE(FORMAT='MED',);

#U4.22.01 mesh=DEFI_GROUP(reuse=mesh, MAILLAGE=mesh, CREA_GROUP_MA=_F(NOM='TOUT', TOUT='OUI',), CREA_GROUP_NO=_F(TOUT_GROUP_MA='OUI',),);

#U4.41.01 #@Eff@#AnalysisType#Mechanical - Beam model=AFFE_MODELE(MAILLAGE=mesh, AFFE=_F(TOUT='OUI', PHENOMENE='MECANIQUE', MODELISATION='POU_D_T',),);

#U4.42.01

#@Eff@#ElemList#Beam;Rectangle;Guide;5;Equal Thickness;100;50;NA;NA

element=AFFE_CARA_ELEM(MODELE=model, POUTRE=_F(GROUP_MA=('Guide', ), SECTION='RECTANGLE', CARA=('HY', 'HZ', 'EP',), VALE=(100, 50, 5, ),),);

#U4.43.01 #@Eff@#MaterialList#CS;2.1e5;0.3;7.8e-9;All CS=DEFI_MATERIAU(ELAS=_F(E=2.1e5, NU=0.3, RHO=7.8e-9,),);

#U4.43.03 material=AFFE_MATERIAU(MAILLAGE=mesh, AFFE=(_F(TOUT='OUI', MATER=CS,),),);

#U4.44.01 #@Eff@#BCList#D.O.F (DDL) on Node Group;Fixed;Fix;0;0;0;0;0;0;NA;NA Fixed=AFFE_CHAR_MECA(MODELE=model, DDL_IMPO=_F(GROUP_NO='Fix',DX=0,DY=0,DZ=0,DRX=0,DRY=0,DRZ=0,),);

#U4.44.01 #@Eff@#LoadList#ForceZ;Force on Node;Load;NA;NA;2000;NA;NA;NA ForceZ=AFFE_CHAR_MECA(MODELE=model, FORCE_NODALE=(_F(GROUP_NO='Load', FZ = 2000,),),);

result=MECA_STATIQUE(MODELE=model, CHAM_MATER=material,CARA_ELEM = element, EXCIT=(_F(CHARGE=Fixed,),_F(CHARGE=ForceZ,),),);

#U4.81.04

result=CALC_CHAMP(reuse=result, RESULTAT=result, CONTRAINTE=('SIEF_ELNO', 'SIPO_ELNO','EFGE_NOEU','SIPO_NOEU',), FORCE=('REAC_NODA',),);

#U4.91.01 #@Eff@#OutputMEDList#SIEF_ELNO #@Eff@#OutputMEDList#SIPO_ELNO #@Eff@#OutputMEDList#EFGE_NOEU #@Eff@#OutputMEDList#SIPO_NOEU #@Eff@#OutputMEDList#REAC_NODA

IMPR_RESU(FORMAT='MED', UNITE=80, RESU=_F(MAILLAGE=mesh, RESULTAT=result, NOM_CHAM=('DEPL', 'SIEF_ELNO', 'SIPO_ELNO', 'EFGE_NOEU', 'SIPO_NOEU', 'REAC_NODA',),),);

#U4.11.02 FIN();

Use this command file in one of your analysis and check results.